Spore Aerosol Generator

The first prototype of the spore aerosol generator applies a horizontal air flow to fungal cultures. Thus, the generation of bioaerosols is possible in a controllable and simple way. This aerosolisation set-up was described in the publication mentioned above and, according to the authors, allows different modes of operation by changing the air velocity. At low air velocities applied to the fungal cultures, aerosolisation of fungal fragments with a size below 1 µm is possible. To aerosolise fungal spores, the air velocity must be increased (Lee et al., (2009)).

Purpose

The Advanced Spores Monitoring (ASMO) project at the Lucerne University of Applied Sciences and Arts is an Innosuisse project in which Agroscope and Swisens are working together to implement real-time aflatoxin and spore monitoring for the food processing industry.

To accomplish the project goal, fungal spores need to be measured with the air-flow cytometer Swisens Poleno, which provides valuable information about bioaerosol particles with holographic imaging and fluorescence measurements.

It is expected that the fluorescence emission of fungal spores and particles in general changes if they are aerosolized by altering their surrounding or state. Therefore, a gentle aerosolization method is needed which is easily controllable and preserves the natural state of the spores. The generation of a dataset of unchanged particles is crucial to eventually detect and classify them in their natural environment.

Development and design

With a similar aerosolization setup designed and built by Swisens AG, we could reproduce the results described in the scientific publication of Lee et al. (2009).

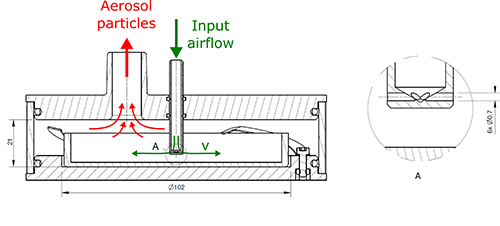

The prototype built by our engineering is designed for holding petri dishes up to 100 mm in diameter. The petri dish is positioned on the ground plate and held down by three metal clamps. To apply a horizontal airflow onto the fungal cultures a tube with horizontal nozzles is placed in the center as seen in Figure 1. To adjust the aerosol generator for petri dishes with different sizes and nutrient mediums, the height of the nozzle pipe can be changed.

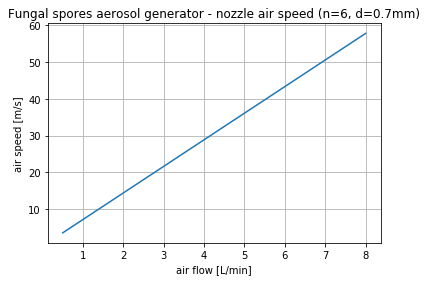

The input air is supplied by a vacuum pump, which can provide an air flow of 1 to 8 l/min. With six nozzles with a diameter of 0.7 mm, this leads to an air speed of up to 58 m/sec on the fungus.

With the use of an external vacuum pump, the aerosol generator has a range of operation as seen in Figure 2. However, it is possible to increase the air velocity on the fungal surface with a compressed air source which can support a higher airflow.

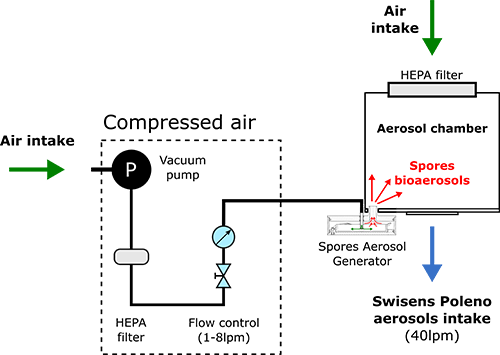

Atomization setup

The bioaerosols generated by the Spore Aerosol Generator are directed into an aerosol chamber located on the aerosol intake of the Swisens Poleno. The aerosol chamber dilutes the generated bioaerosol and ensures that the nominal intake air flow of the Swisens Poleno of 40 l/min is maintained, as the Spore Aerosol Generator delivers a maximum of 8 l/min. It is plugged into the base plate of the aerosol chamber and can be easily removed to change the petri dish.

First experiments and preliminary results

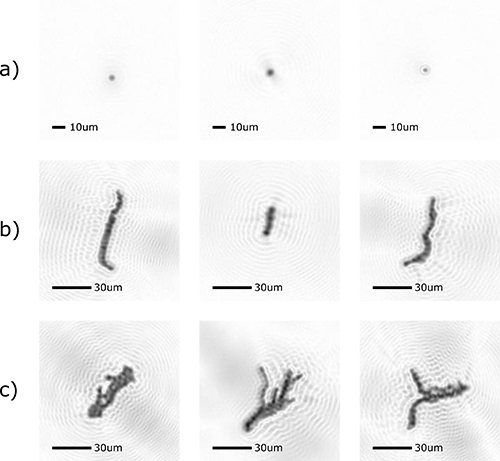

To test the atomization setup and verify the design of our prototype we conducted measurements with the fungus Aspergillus flavus. The conidia spores of Aspergilus flavus are globular with a diameter from 3 to 6 µm. The spores detach from the fungal reproductive structures (conidiophores) as single particles, as chains of multiple spores or as agglomerates of multiple chains of conidia (Figure 5).

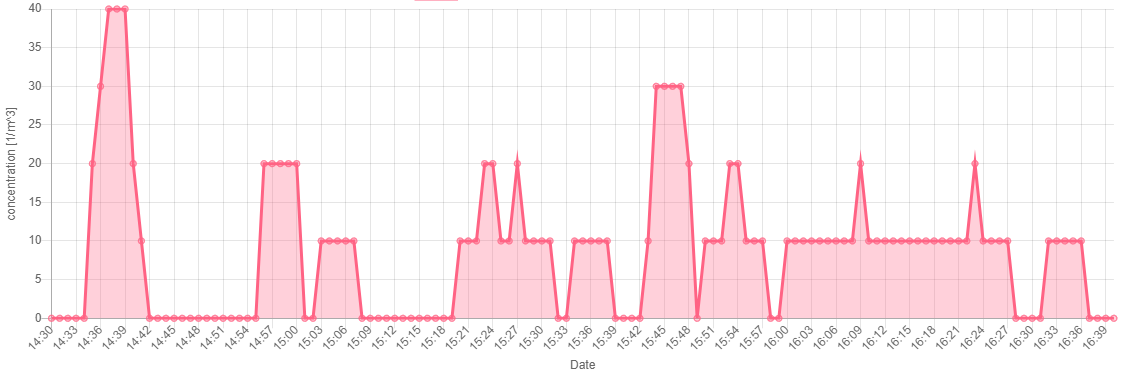

For this experiment a petri dish with Aspergillus flavus was placed into the Spore Aerosol Generator and the airflow was set to 8 l/min, which results in an air velocity of approx. 55 m/sec on the fungal surface. With these settings we were able to generate spore aerosols with a concentration of up to 8000 particles per cubic meter for approx. 30 minutes as seen in the upper graph of Figure 4. To ensure that the measured spores are not spontaneous dischargements, a control sample was measured with a second Swisens Poleno. The comparison of these concentrations clearly shows that the Spore Aerosol Generator produces a peak concentration of 200 times higher than the control sample, therefore spontaneous dischargements of spores can be ruled out.

As a result, different appearances of spores aerosolized from the fungus were measured. In the holographic images taken by the Swisens Poleno, the Aspergillus flavus conidia are recognizable. In the Figure 5 a selection of measured spores are shown whereas Figure 5b and 5c show spore chains and spore agglomerates.

Outlook

In conclusion, with the described set up we are one step further towards real-time measurement and analysis of fungal spores. Meanwhile we want to apply this aerosolization method to other fungal species with spores of different sizes in order to generate data sets with a variety of spore types. The real-time identification of fungal spores with the Swisens Poleno using holographic imaging and fluorescence spectroscopy can then be tackled.

If you want to have more information on this topic please send us your questions and requests.